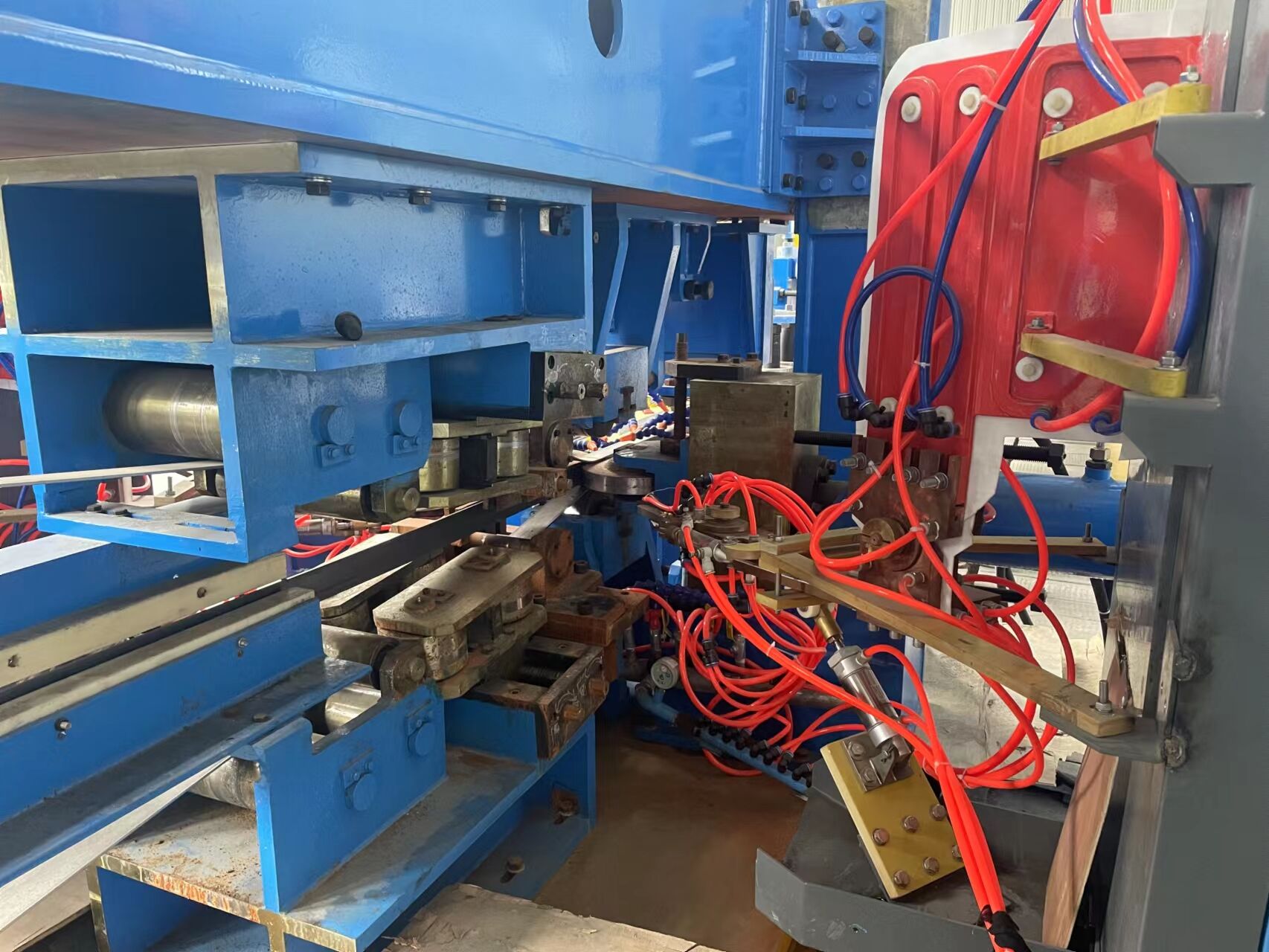

automatic slitting machine factory

"Robot" is a robotic arm designed with the increased capacity and automatic activation required to be classified as one of the first generation robots made by General Electric Company. Separate parts within this slitting machine factory include various production lines, the cleaning equipment department and the quality inspection rooms. Up to now, it has designed and produced 7 cutting accurate machines with more than 10 thin or ultra-thin material importing patents. The principle functions performed in this factory are mainly that of slitting machines which are made for different materials. These have application in a wide range of fields, from paper and film, through foil to metals such. They employ top level technology in them like PLC program control systems; entire screen touch interfaces for operating ease; automatic tension systems. Our products are widely used in packaging, printing and converting. When these materials have to be cut into specific widths at high precision and speed the machine is then indispensable. The factory places great emphasis on scientific management and efficiency, thus ensuring that every slitting machine is of the highest quality and most reliable type.